Manufacturing of Medical Components

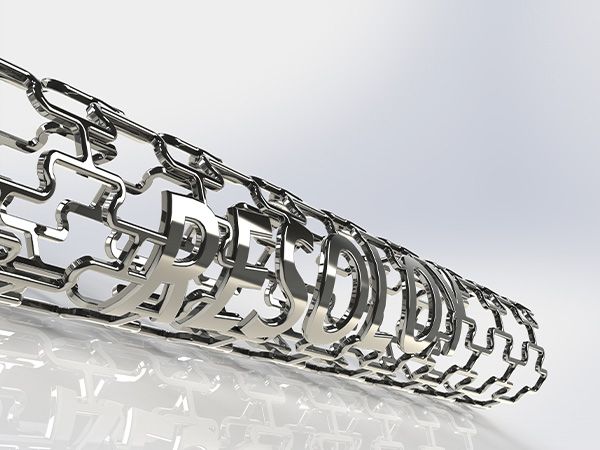

As a contract manufacturer and solution provider, MeKo produces medical components of all kinds. Based on the drawings and specifications of our customers, we manufacture components with minimal tolerances and perfect surface quality. MeKo pioneered stent manufacturing as early as 1995. Today, we are among the largest contract manufacturers of medical components worldwide and are perceived as quality leaders. Thanks to unique manufacturing processes and our expertise, we also implement the most demanding projects.

We partner with our customers to enable the development of safe, innovative, and affordable medical devices to improve healthcare globally.

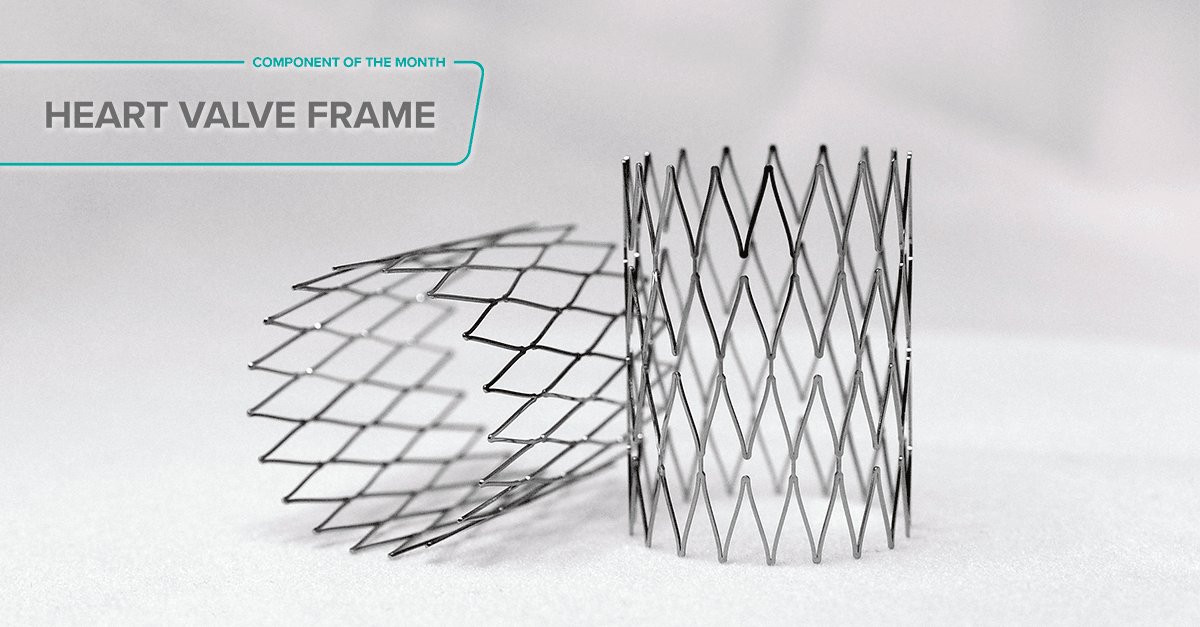

Implants, Instruments, and Orthopedic Components

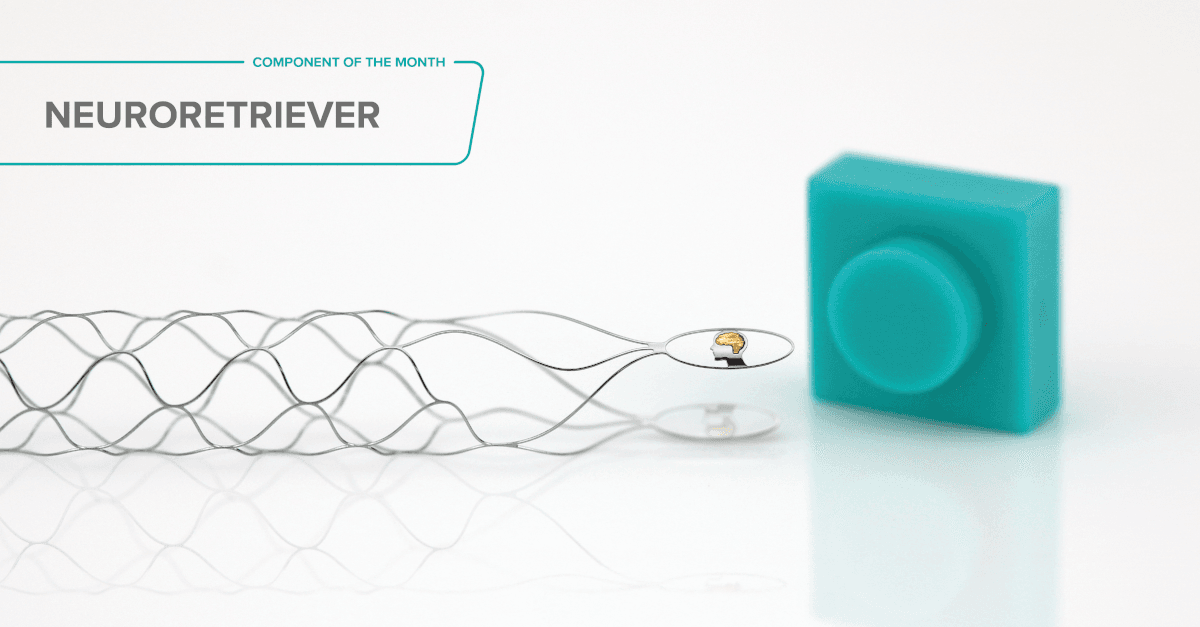

MeKo's manufacturing processes can be adapted to almost any design. We produce implants for all medical areas, such as cardiology, radiology, neurology, ophthalmology, and urology.

Full Flexibility for Your Components

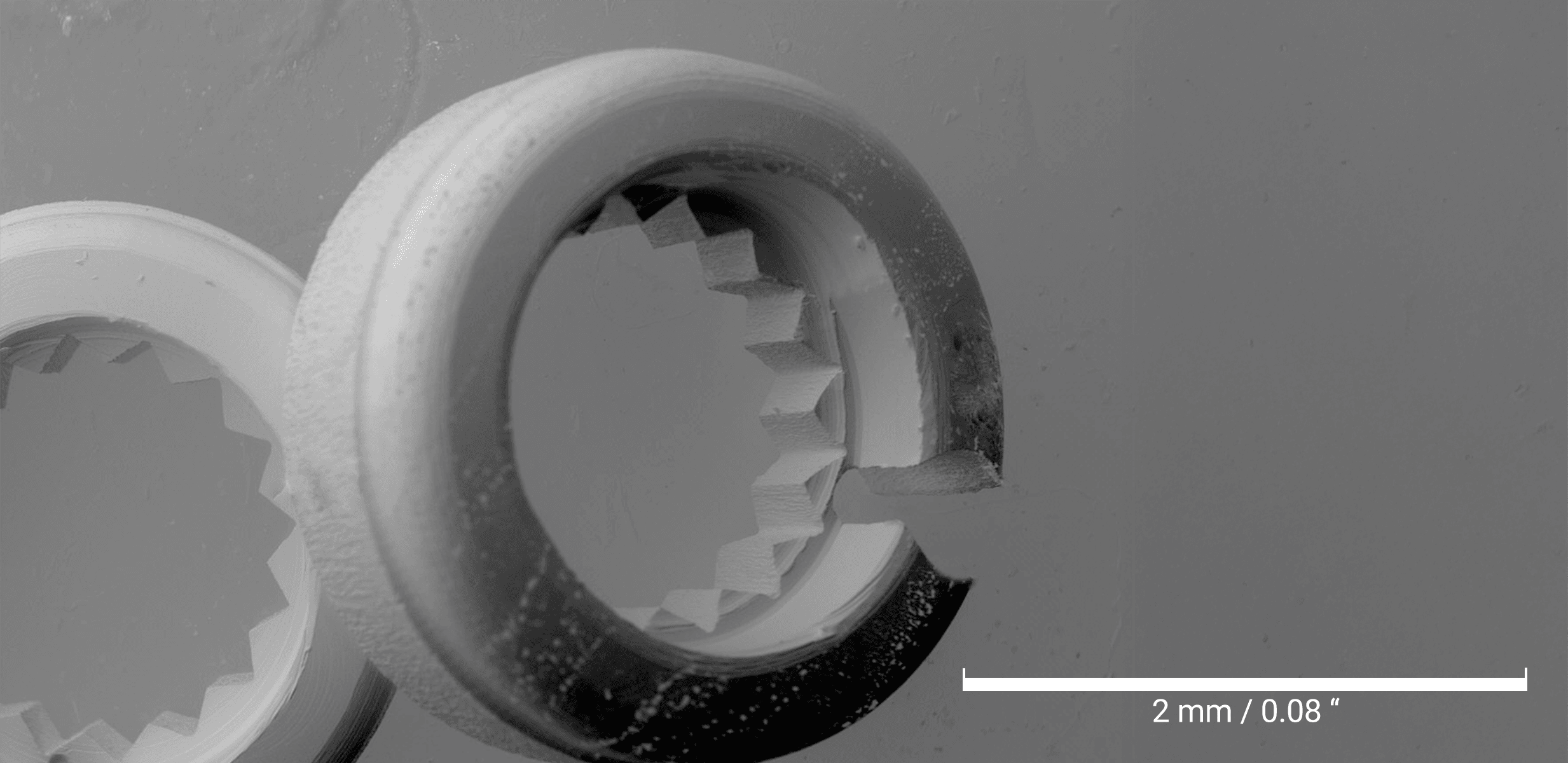

With our extremely precise laser systems, we process flat and tubular materials such as stainless steel and nickel-titanium, as well as new bioresorbable materials made of magnesium and polymers. Over 2,000 materials and tube sizes are available.

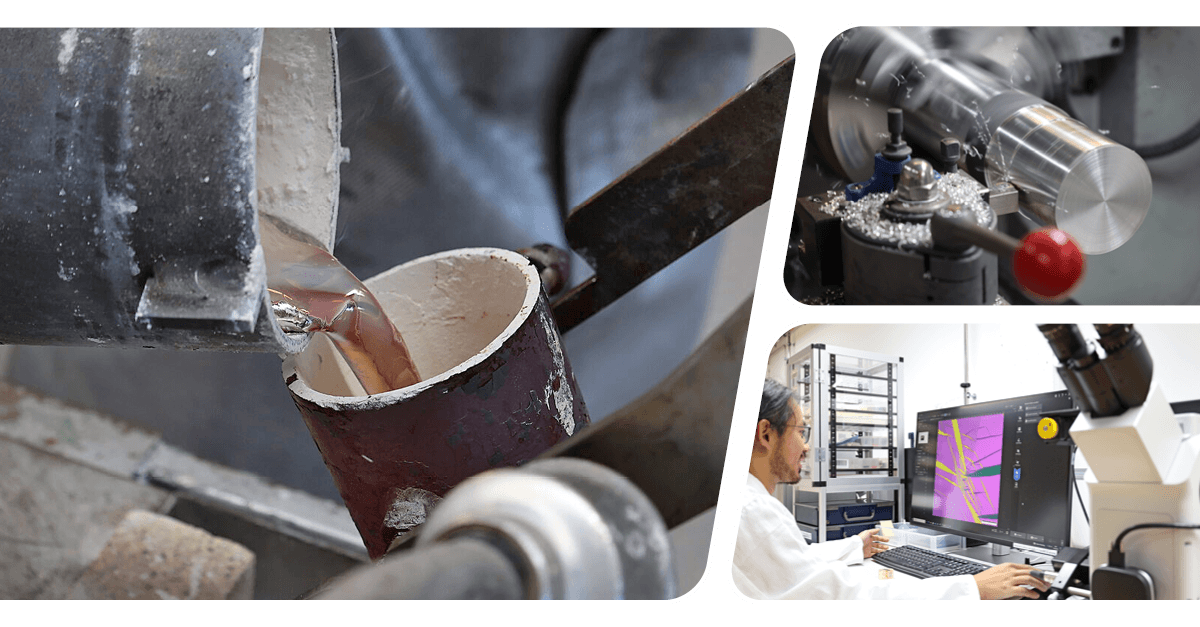

Manufacturing Process

Our manufacturing processes give you the greatest possible freedom in the production of your medical components while guaranteeing the highest quality - from prototype to series production.

Research and Development

We conduct research on new manufacturing processes, materials, and surface modifications - for your competitive advantage.

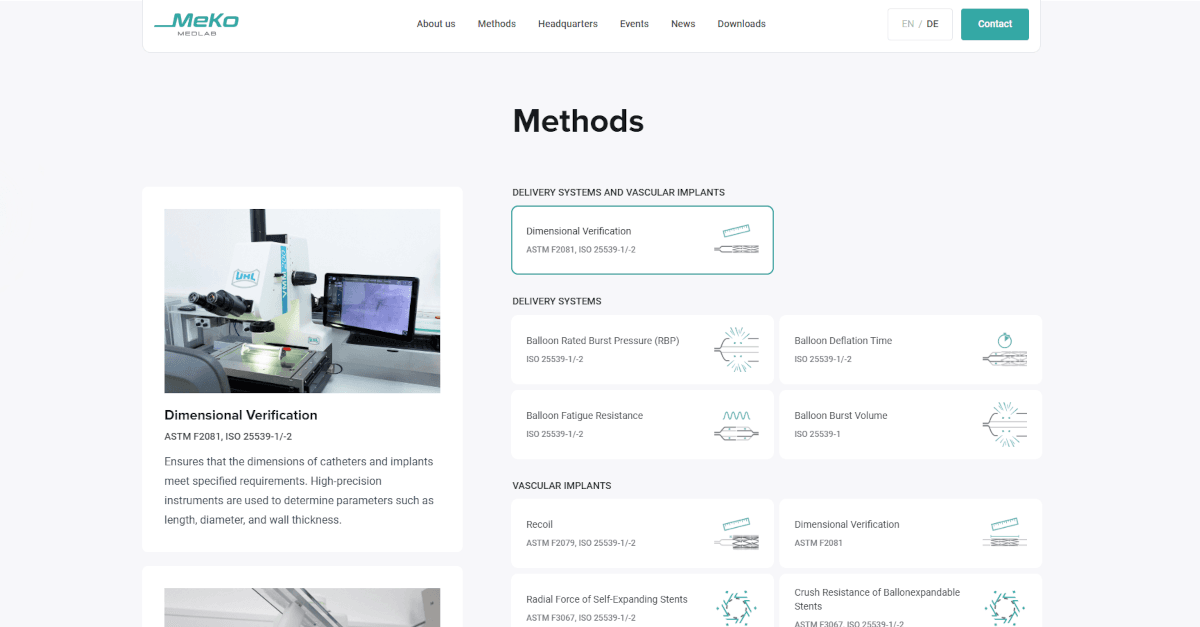

Medlab Laboratories

Our laboratories are equipped with the most accurate measuring technology to analyze medical components and test them using optical and mechanical methods.

100% Visual Inspection

Upon request, medical components undergo 100% visual inspection to ensure impeccable quality.

From Prototype to Series Production

Prototypes are manufactured at MeKo just like serial parts. This enables series-like prototypes and quick, efficient conversion.

What Our Customers Say

Experience Quality

Our extensive checks during production ensure the highest quality standards.

Quality control is equipped with more than 100 specialized high-end microscopes. The final 100% inspection guarantees perfect quality you can trust.

ISO 8 cleanrooms (Class 100,000) are available. Comprehensive tests are conducted in our laboratories.

Book a Personal Online Presentation

Want to learn more about MeKo and our services?

Then book a 30-minute online presentation here and speak directly with one of our engineers.

Come meet us

News

Or conveniently in three simple steps

Our locations

Sarstedt near Hannover

Im Kirchenfelde 12-14

31157 Sarstedt, Germany

USA

8500 Normandale Lake Blvd, Suite 350, Bloomington Minnesota 55437, USA

California

2 Williams LaneFoster City

CA 94404, USA

Costa Rica

Metro Free Zone & Business Park, Building 5C

Heredia, Costa Rica