Marker crimping

Maximum Precision for Optimal Visibility

Radiopaque markers play a crucial role in medical technology, especially for the precise positioning and traceability of stents under X-ray or fluoroscopic imaging. MeKo offers highly precise techniques for integrating these markers through marker crimping and marker welding – to ensure secure and durable fixation. With decades of experience and state-of-the-art manufacturing technology, MeKo delivers customized solutions for integrating markers into stents and other implants. Our focus lies on utmost precision, biocompatibility, and tailored adaptation to our customers’ specific requirements.

Mechanical Bonding for Secure Fixation

In marker crimping, the marker is mechanically pressed into the stent to ensure a secure hold. This method offers several advantages:

- No thermal stress: The stent material retains its original structure.

- Strong bond: Markers are permanently fixed using precise mechanical force.

- Suitable for sensitive materials: Particularly beneficial for bioresorbable or thin-walled stents.

The process is based on high-precision pressing techniques that enable a firm yet material-efficient integration of the marker. By precisely calculating the required force and adapting to the specific stent geometry, we ensure that the markers are fixed without material deformation or undesired tolerance deviations.

Stability Through Laser Technology

For an even stronger bond, markers can also be attached using laser welding. In this process, the marker is fused with the stent, creating a metallurgical joint.

MeKo utilizes cutting-edge laser welding technology to securely and precisely fix markers in implants such as stents. Welding can be performed both automatically and manually to allow for optimal adaptation to the specific stent geometry and material properties.

The stable connection ensures long-term fixation and prevents unintended movement or detachment of the marker. Advantages of this method at a glance:

- Permanent fixation with zero tolerance – even under stress

- Precise and minimally invasive laser weld points

- Flexibility for various designs and materials, tailored to specific customer requirements

This method is especially suitable for metallic stents subject to high mechanical loads or implants with demanding operating conditions. Our precise processes ensure that every welded component meets the highest standards of quality and safety.

SEM-image of a laser welded marker in a Resoloy®-Stent

SEM-image of a laser welded marker in a Resoloy®-Stent

Maximum Flexibility in Marker Sizes

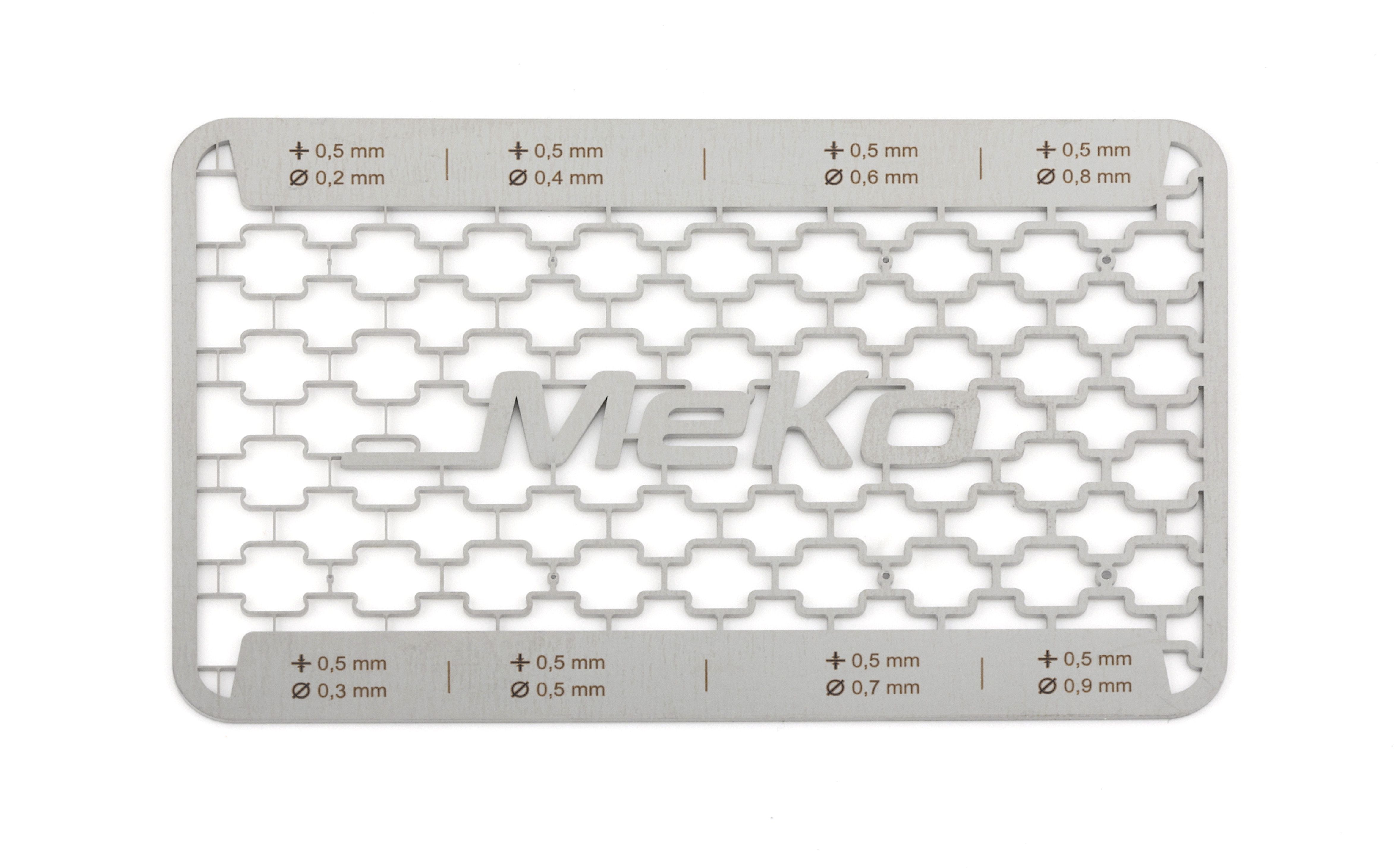

Choosing the right marker size is critical for optimal visibility and reliable integration into the implant. That’s why we actively support our customers in selecting the right markers and offer a practical tool for orientation: the MeKo Marker Card.

This card allows different marker sizes to be tested and assessed for suitability in specific applications. This facilitates well-founded decisions early in the development process–optimizing workflows and easing subsequent implantation. Learn more in our blog.

Contact us to learn more about our marker crimping and welding solutions. We’ll be happy to advise you!