MeKo’s New Radiopaque Marker Test Plate

Selecting the optimal radiopaque markers for implants such as stents is a crucial step in medical device development. The right marker size ensures clear visibility under fluoroscopy, aiding precise placement and improving procedural outcomes. To simplify this selection process, MeKo has developed an innovative radiopaque marker test plate.

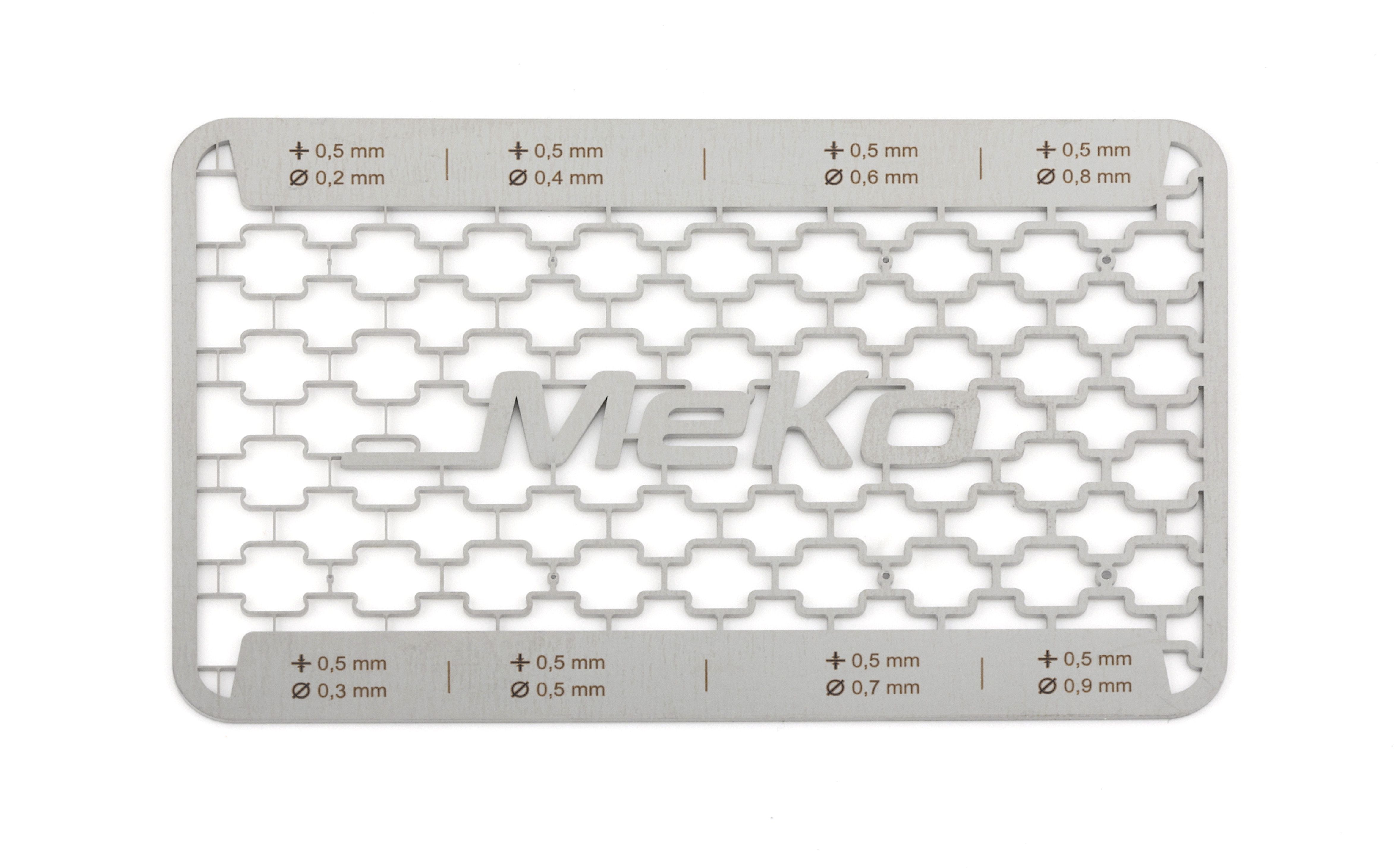

Designed in the shape of a credit card, the test plate is instantly recognizable and easy to handle. The test plate itself is made of Nitinol and incorporates tantalum markers with increasing diameters and varying strut widths. The structured arrangement allows engineers to directly compare marker visibility under fluoroscopy and quickly determine the most suitable configuration for their specific applications. The stent-like design was chosen to closely replicate real-world conditions, ensuring that marker behavior and visibility match actual clinical use as closely as possible.

Faster Development – Reliable Benchmarking

The marker test plate is the result of close collaboration between design, engineering, and customer requirements. By providing a ready-to-use reference, it significantly shortens the development cycle and reduces trial-and-error iterations. Initial X-ray tests show excellent contrast results – markers appear dark against brighter tissue structures, enabling precise orientation and controlled positioning during procedures.

This is especially important in applications where exact placement is critical for therapeutic success. Tantalum was selected due to its excellent radiopacity, biocompatibility, and seamless integration with Nitinol. Unlike gold or platinum, tantalum minimizes galvanic corrosion in combination with Nitinol, ensuring long-term durability and cost efficiency.

A Step Towards More Efficient and Ethical Development

Beyond its technical advantages, the test plate also supports more sustainable and ethical product development. By providing precise fluoroscopic data early in the process, it helps reduce the number of required animal studies while accelerating time to market for new medical devices.

We are continuously refining this solution – future expansions will include additional marker materials and thickness variations to provide even greater flexibility for different applications. With this development, MeKo reaffirms its role as an innovation driver in precision engineering. Partnering with us means gaining access to well-thought-out solutions that streamline workflows and set new industry standards.

With real-world imaging data at your fingertips, we help you make informed decisions – because precision matters in medical device innovation.

Interested in testing our marker plate? Contact our team of experts today!